Dec 19, 2024

Weight transmitters are essential devices in industrial settings, bridging the gap between weight measurement and automated processes.

In this article, we’ll explore how weight transmitters work, their applications, and how to choose the right one for your needs.

We'll also look at leading Weight Transmitter manufacturers in India and why they are essential for precision industries.

What is a Weight Transmitter?

A weight transmitter is a device that converts weight data from a load cell into a signal that can be read by other instruments like controllers, PLCs (Programmable Logic Controllers), or data acquisition systems. This enables real-time weight monitoring in industrial automation systems.

Core Components of a Weight Transmitter

Input Module: Processes signals from load cells.

Analog-to-Digital Converter (ADC): Converts analog weight signals to digital outputs.

Communication Interfaces: Allows integration with external systems using protocols like Modbus, Ethernet, or RS485.

Power Supply: Powers the transmitter and connected sensors.

Output Interface: Sends weight data in readable formats like 4-20mA, 0-10V, or serial communication.

Key Features of Modern Weight Transmitters

High Precision: Advanced ADCs provide accuracy up to micrograms.

Versatile Connectivity: Compatible with both digital and analog systems.

Compact Design: Space-saving, ideal for panel mounting.

Durability: Engineered for harsh environments, resistant to temperature and vibrations.

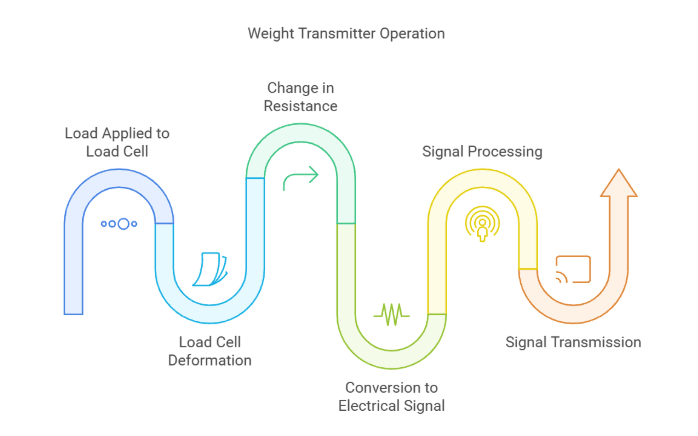

Working Principle

The fundamental operation of a weight transmitter involves the use of load cells, which are sensors that detect weight. When a load is applied to the load cell, it deforms slightly, causing a change in resistance. This change is proportional to the weight applied and is converted into an electrical signal. The weight transmitter then processes this signal and transmits it to a display or control system.

How Does a Weight Transmitter Work?

Signal Reception: A load cell measures the force exerted by a load and converts it into a low-voltage analog signal.

Signal Processing: The transmitter amplifies and filters this signal to eliminate noise.

Conversion to Digital: The ADC converts the analog signal into digital data.

Data Output: The processed weight data is transmitted to controllers or monitoring systems in formats like 4-20mA or Ethernet signals.

Example of a Weight Transmitter Application

In a food processing plant, weight transmitters are used to monitor and control the weight of ingredients on a conveyor belt. The system ensures precise ingredient ratios, reducing waste and improving product quality.

Applications of Weight Transmitters in Industries

Weight transmitters are indispensable in various industries. Below are some real-world applications:

1. Manufacturing

Automated assembly lines use weight transmitters for precise part measurement.

Monitors material feed in extrusion processes.

2. Logistics and Warehousing

Tracks the weight of packages for accurate billing.

Used in conveyor systems to sort items by weight.

3. Food and Beverage Industry

Ensures consistency in batch processing.

Integrated into filling machines for accurate product dispensing.

4. Chemical and Pharmaceutical Industry

Assists in dosing raw materials with high precision.

Essential in mixing operations to ensure formula integrity.

5. Mining and Aggregates

Measures bulk material in hoppers and silos.

Ensures compliance with load restrictions.

Benefits of Using Weight Transmitters

Accuracy: High-precision measurements improve operational efficiency.

Automation Ready: Integrates seamlessly with industrial automation systems.

Durability: Designed for challenging environments, withstanding dust, moisture, and high temperatures.

Cost-Efficiency: Reduces material wastage and improves process efficiency.

Scalability: Suitable for small operations and large industrial setups.

Leading Weight Transmitter Manufacturers in India

India is home to several reliable Weight Transmitter manufacturers offering state-of-the-art devices for industrial automation. Some noteworthy players include:

LCS CONTROLS: Renowned for their weight transmitters tailored to diverse industries.

For those seeking detailed specifications, explore LCSCON’s range, including the Weight Transmitter 10 and Weight Transmitter 50.

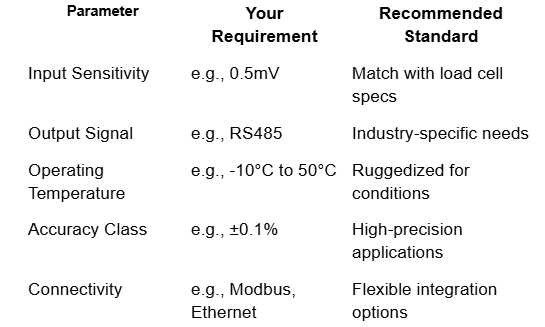

Choosing the Right Weight Transmitter

Selecting the appropriate weight transmitter can significantly impact the efficiency and accuracy of industrial processes. To make an informed decision, you need to consider various factors, including technical specifications, compatibility, and industry-specific requirements.

Key Factors to Consider

Load Cell Compatibility

Ensure that the transmitter is compatible with the type and capacity of your load cells. Check parameters such as input sensitivity and excitation voltage.Example: A high-capacity hopper scale may require a transmitter with higher excitation voltage.

Signal Output Type

Choose between analog (4-20mA, 0-10V) and digital outputs (RS485, Modbus, Ethernet) based on your system's requirements.Tip: Analog signals are simpler but less versatile than digital outputs for complex systems.

Accuracy and Resolution

Look for high-resolution ADCs and accuracy ratings that match your operational needs.Industry Standard: Transmitters with a resolution of 24 bits are ideal for precision-critical tasks like pharmaceutical mixing.

Environmental Factors

Consider transmitters designed to withstand environmental challenges like temperature fluctuations, humidity, or vibrations.Example: In mining operations, ruggedized transmitters are essential.

Ease of Integration

Modern transmitters offer plug-and-play interfaces, reducing installation complexity. Ensure compatibility with your existing PLCs or SCADA systems.Size and Mounting Options

Compact designs are ideal for limited spaces, while rack-mount transmitters may suit larger setups.Compliance and Certifications

Look for transmitters that meet industry standards like ISO, CE, or ATEX certifications for hazardous environments.

Weight Transmitter Selection Checklist

How to Maintain and Calibrate Weight Transmitters

Proper maintenance and calibration are critical for ensuring the long-term accuracy and reliability of weight transmitters. Neglecting these aspects can lead to measurement errors, production inefficiencies, or even system failures.

Importance of Regular Maintenance

Ensures Accuracy: Over time, wear and tear or environmental conditions can affect performance.

Prevents Downtime: Regular checks reduce the risk of unexpected failures.

Extends Lifespan: Proper care ensures the device serves you well for years.

Steps for Maintaining Weight Transmitters

Visual Inspection

Check for signs of physical damage, corrosion, or loose connections.

Inspect load cell cables for wear or fraying.

Clean Regularly

Use a dry or slightly damp cloth to remove dust or debris.

Avoid harsh chemicals, as they can damage the device's surface or internal components.

Check Mounting Points

Ensure the transmitter is securely mounted to avoid signal distortion caused by vibrations.

Environmental Protection

Use enclosures if the transmitter is in harsh conditions like high humidity or dusty areas.

For outdoor setups, ensure compliance with IP ratings (e.g., IP67).

Update Firmware

If your weight transmitter supports firmware updates, ensure it is up-to-date for optimal functionality and security.

Calibration: Why and How?

Calibration ensures that the weight transmitter provides accurate readings by aligning its measurements with known standards.

When to Calibrate

After installation or relocation.

Periodically, as recommended by the manufacturer (e.g., every 6-12 months).

After exposure to extreme conditions, such as temperature spikes or heavy loads.

Calibration Process

Gather Equipment

Calibration weights or a certified load cell simulator.

Manufacturer’s calibration manual.

Initiate Calibration Mode

Follow the manufacturer’s instructions to put the transmitter in calibration mode.

Apply Known Weights

Place calibration weights in increments. Compare readings against expected values.

Adjust Settings

Use the transmitter's interface to fine-tune settings, ensuring readings align with standards.

Verify and Document

Retest with the same weights to confirm accuracy.

Record calibration data for audits and future reference.

Common Calibration Errors to Avoid

Incorrect Weight Standards: Always use certified weights to prevent inaccuracies.

Ignoring Warm-Up Time: Allow the transmitter to stabilize before calibration.

Overloading: Applying excessive weight can permanently damage the load cell or transmitter.

Future of Weight Transmitters in Industrial Automation

As industries embrace automation, weight transmitters are evolving to meet the demands of smarter and more interconnected systems. The integration of advanced technologies is transforming these devices into vital components of modern industrial ecosystems.

1. The Rise of Smart Weight Transmitters

Smart weight transmitters leverage cutting-edge technologies to enhance functionality and ease of use.

IoT Integration: Weight transmitters are now equipped with IoT capabilities, enabling real-time data transmission to cloud platforms for analysis and monitoring.

Remote Diagnostics: With connected systems, operators can monitor transmitter health, performance, and maintenance needs remotely.

For example, a smart weight transmitter installed in a food processing plant can send real-time weight data and notify operators of potential load discrepancies via a mobile app.

2. Enhanced Connectivity Options

The future of weight transmitters lies in their ability to communicate seamlessly with other devices.

Wireless Solutions: Bluetooth and Wi-Fi-enabled transmitters eliminate the need for extensive wiring, reducing installation time and costs.

Protocol Compatibility: Support for industrial communication protocols like Modbus, Ethernet/IP, and Profibus ensures smooth integration with PLCs and SCADA systems.

3. AI and Machine Learning in Weight Measurement

Artificial intelligence (AI) and machine learning (ML) are paving the way for predictive analytics and automated decision-making.

Predictive Maintenance: AI algorithms can analyze trends in weight data to predict when a transmitter or load cell might fail.

Optimization: ML models can optimize processes like batching and blending by analyzing historical data to improve efficiency.

4. Sustainability and Energy Efficiency

The demand for eco-friendly solutions is driving innovations in weight transmitter design.

Low-Power Devices: Manufacturers are developing transmitters with minimal energy consumption to reduce operational costs.

Recyclable Materials: The use of sustainable materials in construction aligns with global environmental standards.

5. Miniaturization and Customization

Industries are seeking compact yet powerful weight transmitters that can fit into smaller systems without compromising performance.

Miniaturized Designs: Advances in microelectronics have enabled the creation of compact transmitters suitable for space-constrained applications.

Custom Solutions: Many Weight Transmitter manufacturers in India, such as LCSCON Controls, offer tailored solutions to meet specific industry needs.

6. Applications in Emerging Industries

Weight transmitters are expanding their footprint beyond traditional sectors like manufacturing and logistics.

Healthcare: Accurate weight measurement is crucial in medical dosing systems and prosthetic manufacturing.

E-commerce: Automated weighing systems powered by transmitters improve parcel handling and inventory management.

The Road Ahead

The evolution of weight transmitters is set to redefine industrial automation, offering businesses greater precision, efficiency, and adaptability. By staying ahead of these trends, Weight Transmitter manufacturers can provide innovative solutions that cater to the growing needs of a connected, sustainable, and data-driven world.

For more information about advanced weight transmitters and their applications, visit the LCS Controls product page.

Conclusion

Weight transmitters play an indispensable role in modern industrial systems by ensuring precise and reliable weight measurement across various applications. As industries evolve, these devices continue to adapt, incorporating smart technologies, improved connectivity, and sustainable features to meet growing demands.

Whether you're managing manufacturing, logistics, healthcare, or e-commerce operations, investing in the right weight transmitter can significantly enhance efficiency, reduce costs, and improve process accuracy. By partnering with trusted Weight Transmitter manufacturers in India like LCS Controls, businesses can access cutting-edge solutions tailored to their unique needs.

Embracing these advancements not only boosts operational performance but also positions businesses to thrive in an increasingly automated and interconnected industrial landscape.

Looking for the best Weight Transmitter manufacturers in India?

LCS Controls is the right Choice!